Centrifuge options include:

Stainless steel centrifuge-bowl assembly

Self-draining centrifuge-bowl / bowl-liner Stainless bowl-liner

Complete stainless steel machine frames

Integrated air-powered feed pump

Integrated progressive cavity feed pump

Integrated motor stop/start station

PLC Timer and VFD motor control panel

Lid latch safety inter-lock

Maximum “G” force: 1,500-x gravity Separating capacity: 1 to 10-gpm

Solids holding capacity: Up to 1.0 gallon Required inlet pressure: 10-psi @ 10-GPM Liquid inlet fitting: 1” NPT

Liquid discharge fitting: 3” NPT

Liquid discharge height: 28”

Liquid discharge pressure: Gravity return Maximum temperature: 160°F

Standard configuration: 6 to 9-pH

316L Stainless configuration: 2 to 14-pH Noise level: 72 dB (A) per 8-hrs.

Drive Motor: 2.0-hp 3 Ph/220/440 volt Dimensions: 34”L x 18.5’W x 20”H Weight: 400-lbs

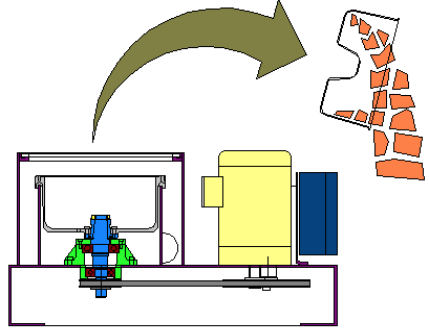

Clean Cycle

After an elapsed time period of process time, the bowl liner reaches its solids holding capacity, and the machine is turned off coasting to a stop. The hinged enclosure cover is unlatched and opened. The bowl lid is removed from the bowl bottom after unscrewing the four SHCS using the provided hex key tool. Using the provided bowl liner lifting tool, the liner is removed from the bowl bottom. The solids are then scraped from the bowl liner, which is then cleaned out and put back into the unit to resume operation.

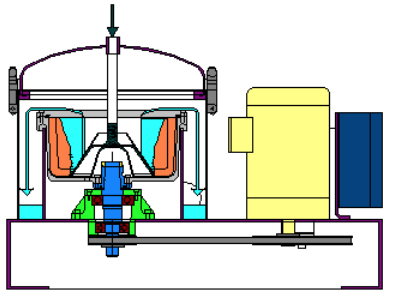

Process Cycle

The dirty liquid continuously feeds through the 1” NPT inlet / feed-tube and into the spinning bowl. The incoming liquid travels under the feed cone and into the bowl chamber where four impeller blades accelerate and maintain the liquid @ full rotational speed. The liquid then travels vertically upward through the bowl. Particles heavier than the liquid separate and move to the perimeter of the centrifuge bowl depositing on the inside wall of the bowl liner forming a dense solids cake that becomes relatively moisture-free under accelerated gravitational force. The clarified liquid exits through the center hole in the bowl lid and into the bowl enclosure where it collects and drains out through the 3” outlet fitting.

| Catalog Number | Description |

|---|---|

| 070D-050 | Lab, Pilot Scale Centrifuge, M512, 2 HP/230 V/3 Ph/60 Hz |